The Vibrating Feeder (Vibratory feeder) is mainly used in feeding materials before coarse crushing. Our series machine can put the block or granule materials from the material storage into the charging device in time evenly and continuously. Therefore. it can realize even feeding for crushers in sandstone production line and make rough screening of materials.The vibrating feeder is widely used to match the crushing and sieving equipments in many industries including metallurgy, coal mine, mineral dressing, building material, chemical, grinding, etc.

Working Principle of Vibrating Feeder:There are two eccentric shafts rotating at high speed at the same time from opposite directions, thus the strong centrifugal force is formed. The component forces of centrifugal force along the vibrating direction will always overlap each other, then counteract with that of vertical force from vibrating direction, then exciting force along single direction is formed to drive the feeder vibrate along straight line. When materials are fed into the feeder, they may be thrown up and move like para curve, then fall dol wn. The materials will move forward on the slope surface of the feeder.

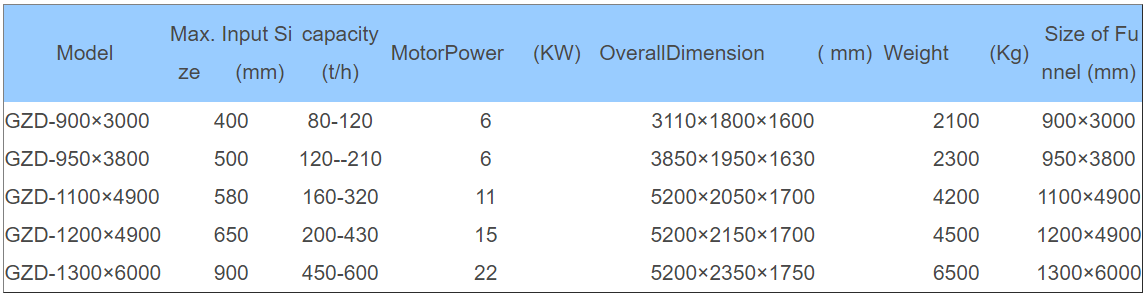

Main technical parameter:

The Vibrating Feeder (Vibratory feeder) is mainly used in feeding materials before coarse crushing. Our series machine can put the block or granule materials from the material storage into the charging device in time evenly and continuously. Therefore. it can realize even feeding for crushers in sandstone production line and make rough screening of materials.The vibrating feeder is widely used to match the crushing and sieving equipments in many industries including metallurgy, coal mine, mineral dressing, building material, chemical, grinding, etc.

Working Principle of Vibrating Feeder:There are two eccentric shafts rotating at high speed at the same time from opposite directions, thus the strong centrifugal force is formed. The component forces of centrifugal force along the vibrating direction will always overlap each other, then counteract with that of vertical force from vibrating direction, then exciting force along single direction is formed to drive the feeder vibrate along straight line. When materials are fed into the feeder, they may be thrown up and move like para curve, then fall dol wn. The materials will move forward on the slope surface of the feeder.

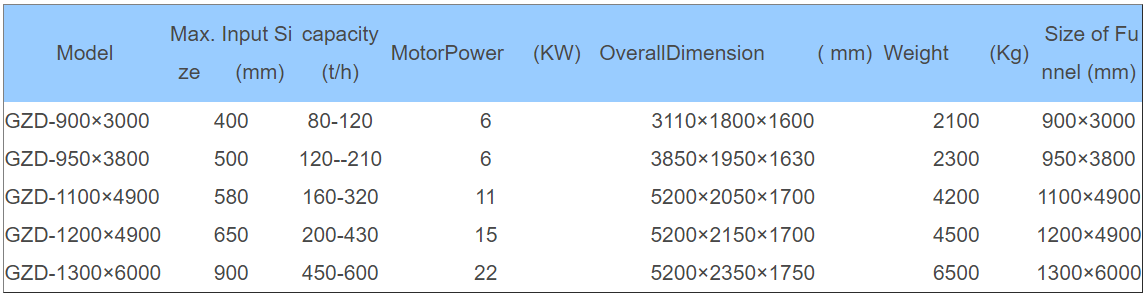

Main technical parameter:

Phone

Tel:+86-16668089029

Top